(BIVN) – Despite the divisive situation ongoing at the base of Mauna Kea, scientists and engineers are hard at work on critical components of the Thirty Meter Telescope in Pasadena, California.

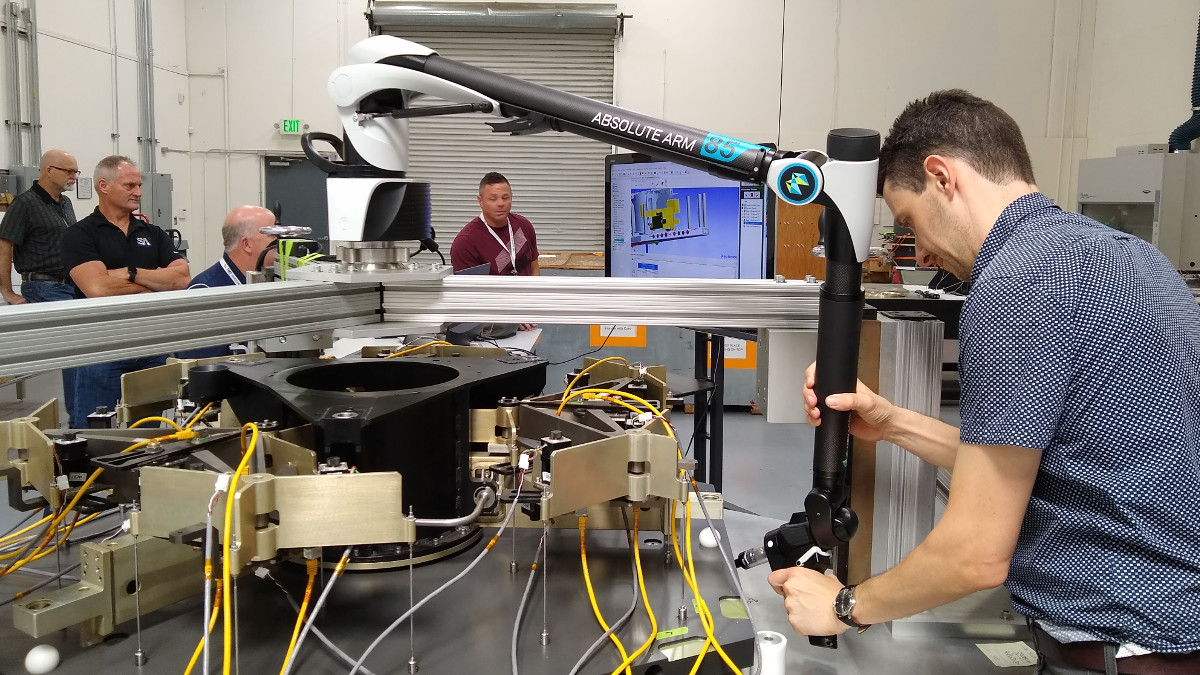

In a September 16 update posted to the TMT website, photos from the TMT Laboratory show new developments within the TMT Quality Assurance program. TMT Engineers are already working with real, full-size components of the primary mirror to see how they fit and work together when assembled, the site reports.

The assembly requires high precision, and engineers are using a new, advanced metrology system to make the measurements.

“We now have a Portable Coordinate Measuring Machine (CMM), which is a great tool for analyzing our assemblies and ensuring we meet the required high-tolerances for the TMT primary mirror. The TMT Optics team and Quality Assurance group have been trained this summer to use this CMM to test the M1 aluminum segment and its support assembly,” says Dr. Alastair Heptonstall, TMT Senior Opto-Mechanical Engineer.

The TMT Primary Mirror System is comprised of 492 active mirror segments, project officials reported in 2017.

According to the TMT International Observatory:

Parts are measured in three dimensions, and compared directly to the original dimensions and tolerances given by the Computer-Aided-Design (CAD) model. Engineers will be able to verify the technical specifications of the telescope’s machined parts and processes.

The accuracy of the measurements provided by the metrology arm is in the range of 25 microns, which is about a third of the diameter of a human hair!

Some tests and study of the mirror cell ergonomics will include:

– Verifying the process for the removal and installation of segments using a lifting jack device, as the segments will be taken out for recoating,

– Inspecting parts such as segment sensor edges,

– Testing the dust boots that cover and keep clean the edge sensors, and

– Assessing the alignment of segments.

These exact same tests will be required and performed at the TMT telescope when it is built and integrated. All material, equipment, parts, components and processes supplied to the telescope will be inspected on arrival to verify and certify their conformity in comparison to their technical requirements. These measuring procedures and the equipment tests used to perform them will assure the accuracy needed for the TMT to perform as expected.

“When parts of the telescope come in, engineers will be able to check them and ensure that the product complies with the specifications and drawings of the CAD model” added Dr. Heptonstall. “Every time we take a segment out to be re-coated we will measure where the edges of the segment are compared to its support structure. This is required to protect every part of the segments, especially the corners of each segment that are particularly vulnerable. As the gap between segments is very narrow, the corners could touch the nearby segments if it is incorrectly positioned. Once mirror segments are placed together, there is a very small and uniform gap of 2.5 millimeter between them. The gap separation is necessary to prevent contact and allow continuous control and maintenance of the segments.”

The goal of the upcoming tests is to verify the positional accuracy of the segment during the actions of docking and undocking, for instance when a segment is removed and replaced at the time of mirror recoating, or during upgrades or maintenance exercises.

The software used by the measuring device is identical to the software TMT will use for the initial alignment of the telescope during its construction. The same metrology and process control will be applied to align the TMT Telescope Optics during the important phase of assembly, installation and verification of the major sub-systems, as well as during operations. This new measuring hardware will be used to ensure and verify the alignment and positioning of all telescope optics: the M1 segments, the primary mirror with the secondary mirror, and the tertiary mirror with the science instruments.

The standoff between law enforcement and opponents of the TMT project is now entering its third month. The ongoing conflict threatens to further delay the observatory that has already taken a decade to get the permits it needs to build on Mauna Kea.

by Big Island Video News6:47 am

on at

STORY SUMMARY

PASADENA, California - Thirty Meter Telescope engineers are already working on full-size components of the primary mirror, according to the TMT website.