KONA, Hawaii: The proposal by OTEC International LLC to construct and operate a 1 Megawatt Ocean Thermal Energy Conversion facility on NELHA’s Hawaii Ocean Science and Technology park has been detailed in a draft environmental assessment.

This facility is a test platform for research, development and demonstration of the OTEC technology; one that the companies involved hope will lead to larger, commercial OTEC power plants.

The draft EA goes into great detail about the exact location and planned appearance of the energy facility, including the seawater pipes, structures, and parking lots that will be built into the area.

2. Description of the Proposed Action

2.1 OTEC Principles

Ocean Thermal Energy Conversion (OTEC) offers a sustainable alternative to fossil fuel-based technologies presently driving Hawai‘i’s energy economy. Unlike most of the renewable energy systems constructed and contemplated for deployment in Hawai‘i, OTEC is a base load, or firm power technology, producing electricity 24 hours a day, every day. Each megawatt of distributed OTEC power completely displaces equivalent power generated by fossil fuels, thereby precluding the need to import oil and coal that are both economically and environmentally costly. By contrast, non-firm power renewable technologies such as wind and solar photovoltaic do not eliminate the need to maintain fossil-fueled spinning reserve capacity for those times when wind and solar energy sources are absent or reduced. OTEC power facilities may be located in close proximity to major coastal cities with access to deep water. Unlike geothermal power in Hawai‘i, whose resources are restricted to certain areas of the Big Island, OTEC facilities would not require expensive inter-island cable systems to transmit power to load centers. The surface of the ocean is the largest collector of solar energy in the world. The temperature of the ocean surface in equatorial zones between approximately 20 degrees north and south of the equator averages 80ºF. Cold water at approximately 40ºF circulates at a depth of 3000 feet (915 meters). By drawing in large quantities of warm surface water to boil ammonia, an ideal gas is produced to generate electricity using conventional turbine-generators. Cold deep ocean water is used to convert the ammonia vapor back to a liquid for recycling in a closed loop system. The key technical challenge for OTEC is to produce enough gross energy to run its power-intensive production facility and to efficiently generate net energy at competitive prices for the electric grid.

OTEC power plants can be land-based or offshore facilities. For land-based plants, the required large volumes of warm and cold seawater are pumped through long intake pipes extending from the shore-based power plant to the appropriate ocean depths. After passing through the OTEC power cycle, the water may be used for other beneficial purposes or returned to the ocean in an environmentally appropriate manner. Land-based OTEC plants have a higher parasitic load (i.e., internal energy demand) relative to offshore plants due to the pumping load required to bring large volumes of water onshore. OTI believes that land-based plants are appropriate for OTEC research facilities, but they do not generate the economic returns, at this time, to be commercially viable. Offshore OTEC power plants include water intake and power generation systems on site that are positioned in deep ocean water, generally several miles from shore. The first generation of OTI-designed commercial plants will be offshore facilities.

Initially, the plant will operate as an integrated test facility and as an important final step before offshore commercial deployment. Over the term of the lease, OTI will introduce and test technology enhancements to optimize the power cycle and to explore the full range of commercial opportunities.

2.4 OTI OTEC RD&D Facility Inputs

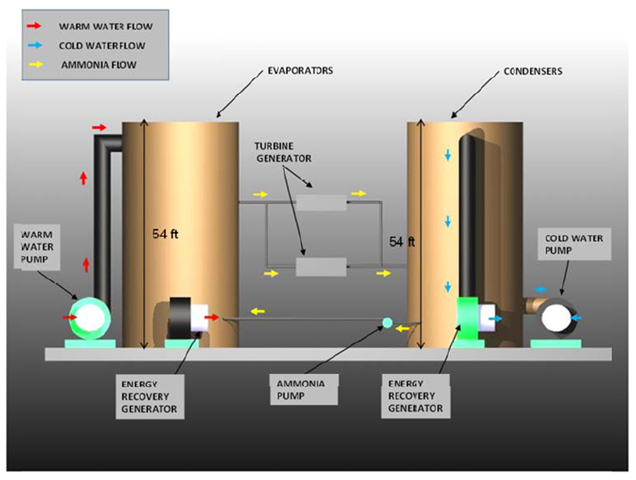

OTEC evaporators transfer solar thermal energy stored in warm surface ocean waters to liquid ammonia causing it to boil, producing a working, pressurized vapor sufficient to power a turbine generator.

At the condenser side of the OTEC cycle, residual thermal energy in the ammonia vapor transfers to cold deep-sea water, and the working fluid returns to its liquid phase, ready to re-enter the power cycle. Large volumes of both warm surface and cold deep-sea water must be supplied continuously to provide the needed energy source and sink for the OTEC process.

NELHA installed the 55-inch pumping station in 2001 for the purpose of actualizing the installation of a 1MW OTEC demonstration plant at the research and development facility. OTI will not exceed a maximum draw of 40,500 gpm of SSW and 27,000 gpm of DSW. OTI will be able to draw up to 45,000 gpm of SSW and 30,000 gpm provided they submit for review to NELHA documentation from the pipe manufacturer that the pipe will not fail at these levels and obtain prior written approval from NELHA to increase the volumes.

The pipeline design capacities were estimated to be the required flow for a 1MW (gross electrical output) OTEC plant which was to be built by KAD Partners to support its development of an aquarium, lobster farm and visitor center. The pumping capacity and the 1MWe OTEC facility were assessed in the Final Supplemental Environmental Impact Statement, Development of Land Exchange Parcel, State of Hawai‘i, Natural Energy Laboratory of Hawai‘i Authority, September 1992 (GK & Assoc., 1992). These facilities were never developed due to financial constraints.

Demand from the 55-inch pumping station is considerably less than the existing capacity. The current demand for DSW and SSW from existing HOST Park tenants is approximately 14,000gpm (J. War, pers. comm.).

OTI proposes to utilize the 55-inch pumping station at its design capacity less the requirements of existing tenants and has developed a resource utilization plan that is responsive to all stakeholders. Specifically, OTI proposes to acquire and install new mixed flow wet pit discharge pumps: one 27,000gpm DSW pump and one 40,500gpm SSW pump. The existing pumps are not made of corrosion resistant materials, operate on only 480VA and have less than ten years of service life. The pumps that OTI will supply, at no cost to NELHA, will be made of corrosion resistant materials wherever there is a seawater interface, will operate on 4160VA, and will have a design service life of 25 years or more. The pumps will be installed with Variable Frequency Drives (VFD) so that as demand fluctuates, flows can be controlled accordingly.

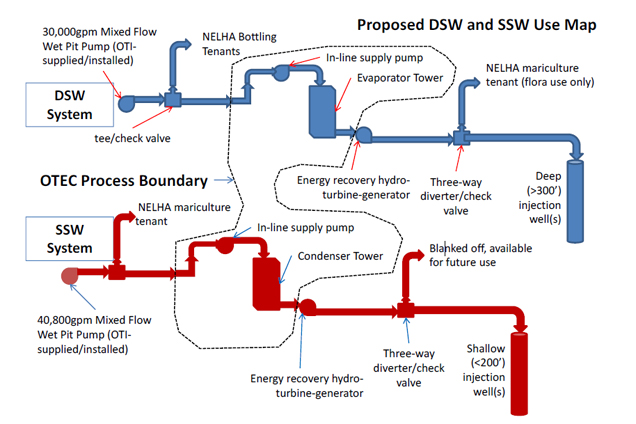

2.4.1 Deep Sea Water – 25,400gpm

The 55-inch NELHA DSW pipe has a design capacity of 27,000gpm (Table 1), but not all of that water is available for OTEC use. The OTI plant uses ammonia as the working fluid. The ammonia flow is designed as a closed system that never comes in contact with water; however, there is always some risk for an ammonia leak into the seawater. While ammonia is a welcome additive to water going to algae and plant life, in sufficient quantities it can be harmful to small marine animals. In addition, any DSW required by the bottling operations must be “untreated” deep ocean water. Therefore, the bottling tenants and some mariculture operations will be supplied from a line that bypasses OTI’s plant, diverting approximately 1,600gpm and reducing available flow for OTEC to 25,400gpm. During installation of the new DSW pump, a “Y” with cut-off and back-flow check valves will be installed in the primary DSW discharge line and connected to existing piping currently delivering DSW to the bottling operations. The balance of DSW will go to the 1MWe OTEC plant, since downstream uses will be limited to plant culture (Figure 6).

2.4.2 Surface Sea Water

Alterations planned for the HOST Park piping system call for some SSW to be diverted to shrimp farming. These shrimp are the breeding stock for many of the shrimp farms around the world. Approximately 1600gpm of SSW must be diverted to this purpose prior to the OTEC plant. Present demand for warm SSW mostly arises from abalone farming operations. As with other marine invertebrates, abalone are sensitive to elevated ammonia concentrations. Current literature suggests that LC-50 for juvenile abalone is in the range of 980 ppb while growth reduction is observed when exposed to chronic levels around 150 ppb over a period of weeks (Aquaculture Volume: 261, Issue: 2, Pages: 678-687, 2006). Big Island Abalone has requested a limit of ammonia in excess of concentrations occurring naturally in DSW to be set to 70 ppb. The 70 ppb limit is derived through personal communication with Trident Seafood personnel and is apparently set to conserve a 2X safety factor over chronic toxicity levels.

The temperature exiting the OTEC evaporators will be nearly the ideal temperature for growing abalone without the delicate and deliberate task of mixing DSW and SSW to obtain the correct temperature. DSW and SSW from the OTEC plant will be returned to the NLEHA-owned distribution system for use by Big Island Abalone and future tenants in the HOST Park. The post-OTEC distribution system will be established with a chemistry monitoring and alarm and activation system connected to diverter valves each side of the OTEC plant. OTI’s resource utilization plan provides for diversion of 6,000gpm of SSW from the input stream to the OTEC process in the event of an ammonia leak resulting in an ammonia concentration above 70 ppb. Of

the remaining 34,800gpm that flows through the OTEC evaporator, a substantial portion is likely to be provided to the kelp and algae farming component of the abalone company, as the possible traces of ammonia will be a welcome addition to the plant culture medium. OTI has met with principals of the abalone farm and the NELHA staff to plan the downstream use of effluent

OTEC water to the maximum benefit of other tenants and the future expansion of the HOST Park.

2.4.3 Electricity

For startup, OTI will rely on electrical power from an on-site mobile synchronous diesel generator. After start up, the OTI 1MW OTEC Demonstration Plant will generate all of its own power. OTI will install all power block equipment necessary to assure frequency and cycle compatibility with the HELCO grid. Any electrical power in excess of the demands of the OTI 1MW OTEC Demonstration Plant can safely power the discharge pumps at the HOST Park 55- inch Pumping Station and the net power output can be safely delivered to NELHA’s tenants or other third parties. Underground power conduits will be installed to those recipients. The power transmission system will conform to current design standards and safety requirements.

2.4.4 Fresh Water and Sanitary Sewage Discharge

The domestic water supply for the Host Park facility is near its maximum permitted capacity. There is a possibility that domestic water may not be available, so OTI will consider collecting fresh water condensate from the facility for sale or distribution to other NELHA tenants. Condensed fresh water should be of good quality, but no testing, certification, or other processing will be undertaken by OTI; therefore, the fresh water should not be considered potable. The usual staff loading for the facility will be three to four persons. Potable water will be used for drinking and hand washing. Statistically water and wastewater for non-residential applications is 25 GPD per individual. The administration building will be capable of accommodating visitors and meetings will be held at the site. Bathroom facilities will be oversized to accommodate additional personnel. Water and wastewater demands are expected to average 100 GPD.

The 1MWe RD&D facility will have its own wastewater disposal system. It will be designed, built and permitted in compliance with Hawai‘i Department of Health permit regulations.

2.5 OTEC RD&D Operating Processes

The OTI RD&D facility is intended to demonstrate and refine the thermodynamic, fluid dynamic, electro-mechanical and electrical performances and safety features of the OTI OTEC power block. OTI believes that a long-term, land-based RD&D facility is more prudent from a risk, operations, and cost perspective than a small-scale, offshore facility. A land-based plant, however, has parasitic loads that adversely affect its performance as compared to OTI’s offshore commercial design. These additional loads must be isolated and accounted for to accurately model the true net performance of OTI’s power cycle and to scale the demonstration results to its commercial offshore plants.

The power block components will be scaled to produce 1MWe gross within the OTEC process boundary (Figure 6). Net power from the commercial simulation will be between 580kW and 890kW. Monitoring equipment will measure the additional intake pumping and discharge requirements and the partial recovery of power through ancillary hydro-turbines to distinguish the net performance of the land-based RD&D plant from OTI’s offshore commercial facilities. At full capacity, the 1MWe facility is expected to produce between 320kW and 640kW in excess of internal demand for third party distribution.

2.5.1 Pumps

New mixed flow wet pit discharge pumps will be installed: one 27,000gpm DSW pump and one 40,500gpm SSW pump. These variable frequency drive (VFD) pumps will operate on 4160VA, and will have a design service life of 25 years or more.

2.5.2 Heat Exchangers (HX) There will be two circular HX towers, each containing two chambers. Between the two towers

will be two turbine-generator decks, which will also house the switchgear and transformers.

These decks will be elevated so that the lower of the two decks will be at least 10 feet above mean sea level to prevent inundation from any ocean surge. Each HX tower will stand about 54 feet above ground level. Water will flow vertically through these towers at rates of about 25,400gpm DSW and 35,800gpm SSW. This much water cascading from a height of approximately 54 feet has enormous kinetic energy, so OTI will install an energy recovery hydroturbine generator at the bottom of both HX towers.

Heat exchanger performance drives total power generation, including that required to offset parasitic loads, and it depends on optimizing not only heat flux but also pressure drop and mass flow. Heat exchangers are critical to an efficient OTEC system as they extract energy from the large quantities of ocean water flowing through the system. While heat exchangers arecommercially available and used in a variety of industrial applications, off the shelf equipment has not been optimized for the heat transfer conditions of a low temperature OTEC power cycle that must operate for decades in a marine environment. A central goal of the OTI RD&D facility is to provide continuing testing capability to optimize and the OTEC HX design and other components for coming generations of commercial OTEC deployment.

2.5.3 Power Cycle

The OTEC RD&D facility will not be connected to the Island’s public utility grid. During stabilization, including the 1000-hour operation test, electricity will be discharged to a load bank via the synchronous diesel-generator. This approach assures that OTI’s plant is unaffected by any perturbations in the HELCO grid due to frequency fluctuations or power outages. It will also demonstrate the stability and reliability of the OTEC power plant. A load bank is a device that develops an electrical load, applies the load to an electrical power source, and converts it to heat that dissipates either through air or water.

Following stabilization, OTI will continue to produce electricity, running the plant constantly to emulate a floating OTEC platform supplying electricity to a utility grid. OTI will moderate power output to mimic peak load, nominal load and off-peak (minimum) load. The load bank assures that the plant can continue to operate even if the HELCO grid fails. Because the load bank is water-cooled, electrical energy is converted to heat and put back into the water being discharged from the plant. A sub-stream of DSW leaving the power block could be be routed to the load banks cooling pool and then discharged to the injection wells. In the instance of watercooled load banks, the volume of water to be used is unknown, but only a small fraction of the total discharge stream, Mixing the load bank water discharge with the total discharge stream would mask temperature differences at the injection well head. Air-cooled load banks are being considered and an economical alternative to water-cooled system.

2.5.4 Condensate Water Collection

The HX towers will be made out of steel. The Condenser Tower will contain 40ºF DSW, which will chill the outside surface of the structure. Because the structure will be exposed to the weather, air-borne moisture will collect and cascade down the outside surface of this structure.

The daily collection rate of condensation is estimated to be about 40,000 gallons. Consistent with OTI’s philosophy of maximizing the use of every available natural resource, OTI plans to collect this condensation and make it available for agricultural use. The production of agricultural quality water can be increased by passing DSW discharged from the Condenser Tower through cooling coils above collection tanks. This is an opportunity OTI is willing to pursue further if there is sufficient demand. Condensate may be utilized for non-potable use within the facility such as sinks and toilets.

2.6 OTI RD&D Facility Outputs

After providing water required for current NELHA tenants, there remains a need to return excess seawater downstream of the OTEC plant. OTI plans to do this in the manner most widely accepted as having the least potential impact on the environment. Based on the assumptions stated above, DSW effluent will be approximately 20,600gpm and SSW effluent will be

approximately 34,800gpm (Figure 6).

The SSW and DSW will pass through the aluminum heat exchangers of the OTI plant with minimal chemical treatment; OTI may utilize very low concentrations of biocides such as bleach to prevent biofouling of heat exchangers. If microbial film development is observed, present plans call for daily 1-hour applications to the evaporators only to achieve inlet solutions at a concentration of 0.07 mg 1-1 (70ppb). By comparison the federal drinking water standard for chlorine in drinking water is 4 ppm, nearly 60 times higher. After reaction with oxygen and organic materials the residual chlorine is expected to be negligible at the time of discharge from the system (See section 4.2.4). No other chemicals are used to treat the water. Except for temperature changes, there will be no detectable differences in SSW or DSW as a result of its use.

The OTI OTEC plant uses a sealed closed loop refrigerant system with the refrigerant being ammonia. The water discharged by the plant will be plumbed to go back into the HOST Park distribution piping, an injection well, or a combination of these. The OTEC process will elevate the DSW temperature by approximately 12ºF; the SSW temperature will be lowered by

approximately 9ºF.

2.6.1 Deep Seawater Return

OTI has closely reviewed findings and recommendations of prior seawater return alternatives analyses and has concluded that underground injection provides the greatest benefit and lowest risk of unwanted impacts on the receiving environment. Based on model discharge plume calculations and results of regional hydro-geological surveys including sample well bores, OTI believes that a system of wells 2 feet in diameter and drilled to a depth of 400 feet, with solid casing down to 300 feet will provide adequate capacity to receive the projected DSW return rate of 20,600gpm. Injection pressure will be on the order of 4 feet at the well head. Present plans anticipate meeting the full OTEC DSW return flow with three deep wells. In the event that permeability either falls short of or exceeds expected conditions, injection well development will be adjusted to attain the needed return capacity and an acceptable margin of 15% surplus.

2.6.2 Surface Seawater Return

Results of previous seawater discharge evaluations at the HOST Park lead OTI to conclude that despite the higher volume flow rates, effluent SSW from the OTEC facility may be returned through a system of shallower injection wells. Five wells 2 feet in diameter and drilled to 150 feet are expected to be sufficient. Injection pressure at the SSW well head will be similar to that

from the DSW wells. As with the DSW well plans, provisions exist to make adjustments as needed to achieve the required capacity.

2.6.3 Generated Power Distribution Following the initial 1000-hour test, OTI will continue to produce electricity, running the plant constantly to emulate a floating OTEC platform supplying electricity to a utility grid. This means that OTI will moderate power output to mimic peak load, nominal load and off-peak (minimum) load. OTI may supply electricity to one or more NELHA tenants or possibly third parties on a cost-reimbursement basis. Underground power conduits will be installed to those recipients. The power transmission system will conform to current design standards and safety requirements. The power that OTI produces will be constant frequency and voltage because OTI will be running induction generators. By designing and connecting the power circuitry through a standby diesel Draft EA OTI RD&D Facility generator, if there is an outage in the HELCO grid, a steady supply of electricity can be provided to the NELHA 55” pump station to sustain seawater flows.

by Big Island Video News10:06 am

on at

STORY SUMMARY

KONA, Hawaii: The proposal by OTEC International LLC to construct and operate a 1 Megawatt Ocean Thermal Energy Conversion facility on NELHA’s Hawaii Ocean Science and Technology park has been detailed in a draft environmental assessment. This facility is a test platform for research, development and demonstration of the OTEC technology; one that the companies […]